- #Eagle arc flux cored wire generator#

- #Eagle arc flux cored wire manual#

- #Eagle arc flux cored wire plus#

Only 1.3 gallons/hour at 210 amps DC, 25V, 100% duty cycle. Oil drain extension for easy oil changes. 2 cylinder, 4 cycle overhead valve air-cooled design.  9,000 watts continuous power for generator, plasma cutter or inverter welder.

9,000 watts continuous power for generator, plasma cutter or inverter welder. #Eagle arc flux cored wire generator#

10,500 Watts Surge Single-Phase AC Generator Power. (4.5 m) of #2 work cable and work clamp to get you started! MIG, flux-cored and basic TIG welding in constant current mode (with optional equipment). Smooth DC welding output for a broad range of stick electrode types. 100.7 dB sound power (Lwa) at rated output. Low noise - 76.4 dBA sound level at 23 ft. And with 10,500 watts of surge AC generator power, it handles a variety of other jobs: lights, grinder, Lincoln Electric inverter, plasma cutter (separate air supply needed) or emergency power. #Eagle arc flux cored wire plus#

Make Work Fly with an Eagle™ 10,000 Plus!Ī great choice for getting the job done! For construction contractors, maintenance crews, farmers or ranchers, the Eagle™ 10,000 Plus does a variety of basic welding jobs. Process Industries Pressure vessel, storage and piping manufacturers, with a focus on onshore petrochemical and refineries.Structural The fabrication, erection and maintenance of buildings, bridges and other architectural structures.Shipbuilding Advanced processes and automated solutions for critical and unique shipbuilding requirements.Power Generation Equipment, consumables and automation solutions for carbon-based, bio-fuel and renewable fuel generation.Pipe Mill Welding, cutting and fabrication of large-scale pipe for cross-country and subsea material transfer.Pipeline Equipment, consumables and expert knowledge in the deployment of cross-country or offshore pipeline projects.

Offshore Rig construction, pressure control and process piping for shipyards and offshore oil and gas infrastructure. Maintenance & Repair Extend the life of metal parts that are subject to impact, abrasion or corrosive wear.

Offshore Rig construction, pressure control and process piping for shipyards and offshore oil and gas infrastructure. Maintenance & Repair Extend the life of metal parts that are subject to impact, abrasion or corrosive wear. #Eagle arc flux cored wire manual#

Heavy Fabrication High deposition manual and automated solutions for heavy fabrication equipment and component manufacturers.General Fabrication Fabrication of metal components and assemblies involving bending, forming, cutting and welding.Automotive & Transportation High speed, low spatter and controlled heat input solutions that ensure repeatability and high productivity.Submerged Arc Welder & Feeder Accessories.Powered Air Purifying Respirators (PAPR).Chrome-Moly Alloys Chrome-Moly Alloy products meet the stringent specs for the offshore, power gen, petrochemical and nuclear industries.Metal-Cored Wires Solid and flux-cored wire for high deposition rates with the ability to weld over mild surface contamination.Submerged Arc Flux and wire combinations for single- and multiple-pass welding in automatic and semi-automatic applications.

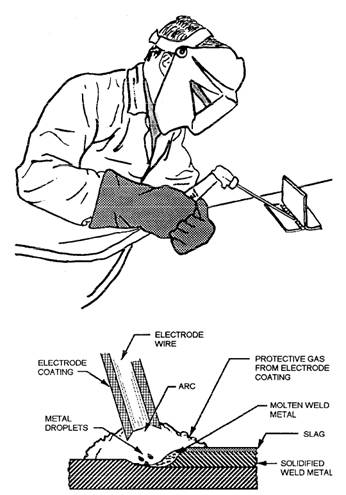

Stainless Alloys Products to meet the process requirements of many stainless steel and high alloy welding applications. Nickel Alloys Products to meet base material and process requirements such as corrosion and high temperature applications. Hardfacing Filler metals for restoring parts that are worn down or adding a protective layer to carbon steel surfaces. Aluminum MIG and TIG Reliable, high quality aluminum MIG and TIG welding products with tight tolerances in chemical composition. Self-Shielded Flux-Cored Brings the productivity of wire welding to outdoor applications, with no shielding gas required. Gas-Shielded Flux-Cored Designed for use with CO2 or argon mixes, our gas-shielded, flux-cored wires deliver superior arc performance. MIG Wires and TIG Rods Filler metals made from the highest quality steel to maximize consistency, feedability and arc performance. Various coating types are available for a wide range of applications. Stick Electrodes For mild and low alloy steel welding.

0 kommentar(er)

0 kommentar(er)